L.A.Y. Precision Machine’s cycle time to bore a hole in a bushing was more than eight minutes. Horn USA’s Supermini type-105 tool system with an HS36-grade boring bar insert reduced this cycle time.

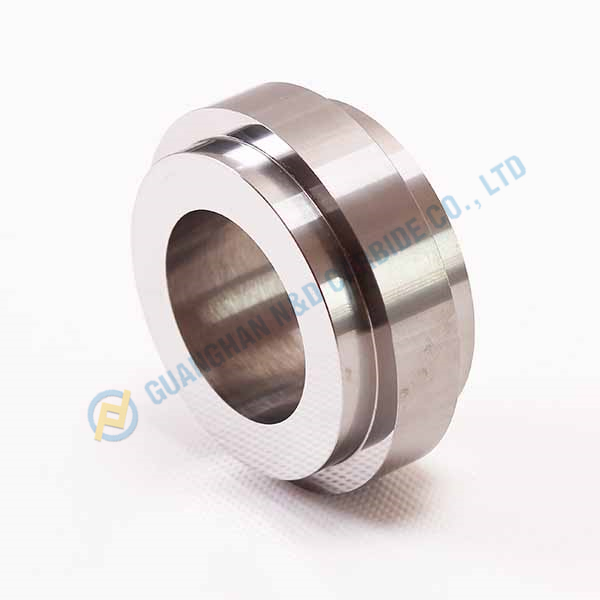

L.A.Y. Precision Machine is a contract shop that specializes in precision Swiss turning and machining, producing parts such as these bushings for hydraulic pumps used in the aerospace industry. tungsten carbide valve units

The shop wanted to improve the cycle time of the bushing, which was more than eight minutes, as well as increase the number of parts made per cutting tool and improve the surface finish.

The Supermini 105 tool system with an HS36-grade boring-bar insert from Horn enabled the shop to reduce the bushing’s cycle time to 1 minute, 23 seconds, turn 75 parts per tool instead of 10 to 15, and improved the surface finish from 38- to 20-microinch Ra.

Small changes can result in big improvements, as Kyle Hawley, owner of L.A.Y. Precision Machine, discovered when he was trying to reduce the cycle time required to hard-turn an aerospace part his shop produces. By switching to a new boring bar from Horn USA Inc. (Franklin, Tennessee), L.A.Y. reduced the cycle time on the part by more than seven minutes.

L.A.Y. Precision Machine was founded in 1946 in Novi, Michigan. Mr. Hawley joined the contract CNC shop as a machinist in 2007, when it moved to West Branch, Michigan, and 10 years later, he and his wife bought it from the family that founded it. The company specializes in precision Swiss turning and machining of aerospace, military, medical and electrical parts. Production volumes range from 100 to 10,000 parts per year.

One such part is a bushing for a hydraulic pump used in the aerospace industry. The shop produces 2,000 of these bushings every year. They are made from 1-inch-diameter 8620 alloy steel barstock that is fed by an automatic bar feeder into a Swiss-style turning machine, where the inner and outer diameters are blanked. The workpieces are sent out for case-hardening to 60 HRC and returned for hard-turning operations. A 1.5-inch-deep hole is then bored into each piece, holding a tolerance of ±0.0005 inch.

Mr. Hawley recognized that the CCMT-type carbide cutting tool insert that the shop was using to bore the hole was causing three specific problems. He says that each corner only lasted for 10 or 15 parts, and the cycle time for each piece was more than eight minutes. He also was not satisfied with the 38-microinch-Ra surface finish that the cutting tool produced.

His cutting tool supplier put him in touch with an application and sales engineer at Horn, who recommended the Supermini 105 tool system with an HS36-grade boring bar insert. The inserts have a carbide substrate, a high-temperature-resistant coating and an adapted cutting-edge geometry specifically designed for hard turning materials ranging to 66 HRC, eliminating the need for cubic boron nitride.

According to Mr. Hawley, the results achieved with the new cutting tool exceeded his expectations. Cycle time was reduced from 8 minutes, 5 seconds to 1 minute, 23 seconds, and each boring bar now can be used for 75 parts. In addition, surface finish Ra improved to 20 microinches. Mr. Hawley says that the boring bar can be changed out quickly, which is an additional benefit. All of this adds up to a 78 percent reduction in manufacturing cost. “Considering we annually make 2,000 of these bushings, time and cost savings really add up,” Mr. Hawley says.

The shop has used the boring bar on other parts with similar effect, he says, including on an Inconel fuel nozzle. The previous cutting tool could machine 20 to 30 pieces, while the new boring bar yields more than 150 pieces.

Mr. Hawley plans to look for more simple improvements like this that his shop can make. “As we continue to upgrade equipment, we’ll be checking in with Horn to help us match the right cutting tools to the jobs. I like that I simply let them know the kind of material we’re working with, and they recommend cutting tool types, grades, and even speeds and feed rates,” he says.

Liquid coolant offers advantages unrelated to temperature. Forced air is the fluid of choice in this shop...but even so, conventional coolant can't be eliminated entirely.

Creating threaded holes in titanium alloys calls for proper techniques based on an understanding of both the properties of these materials and the peculiarities of the tapping process.

Carbide Blanks Rod The many rules of programming CNC cutter radius compensation can make machining problems difficult to diagnose and correct.